Award ID: 21299 Company: PT Kreasi Sanadi Multi

Allgemeine Informationen

- Datum: 2024-06-20 03:53:49

- Firma: PT Kreasi Sanadi Multi

- Ansprechpartner: Mr. Andre Rochman

- E-Mail: andre.rochman@ksm-engineering.com

- Anschrift: Jl. Lanbau No. 111, RT.005 RW.05 Desa Leuwinutug – Kec. Citeureup Kab. Bogor, 16810 Bogor

- Telefon: +62 857-0261-7670

- Land: Indonesia

- Awareness:

Application description of the installation

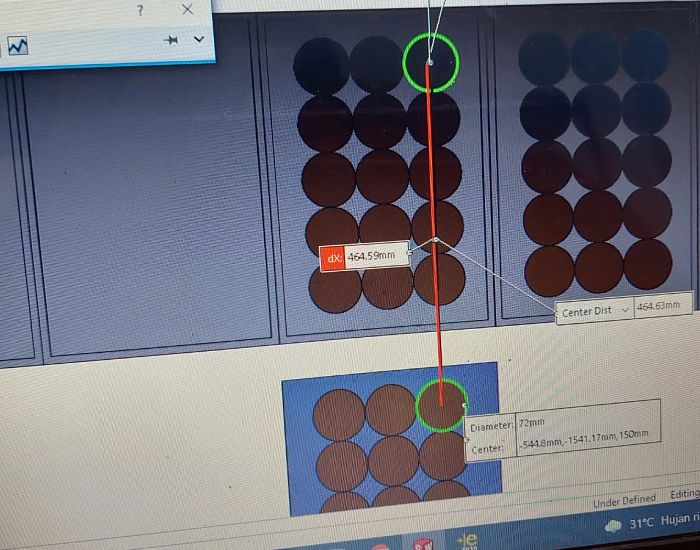

application for loading ice cream cups from filling machine to plastic tray ( Pick and place ice cream products), have 2 type products cone ice cream and cup ice cream with different dimension,

before use man power for pick and plce from tray to conveyor and from conveyor to tray box

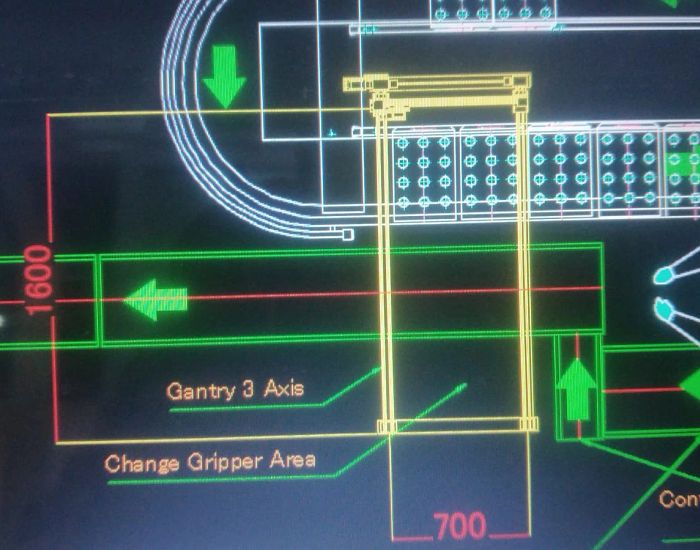

propose 2 type gantry system with different workspace

before use man power for pick and plce from tray to conveyor and from conveyor to tray box

propose 2 type gantry system with different workspace

Problem definition

1 proces have a 3 man power for production, loading ice cream cup from filling machine to plastics tray ( 15 cups/tray ) sometime can not achieve targeted 15 cup/tray

How were processes optimized/costs saved/increased efficiency with automation?

management want reduce man power and also increase processing

after used room gantry system can optimized process and cost saving because reduce 2 man power, 1 line production before use 3 man power and now only 1 man power for handle line production

after used room gantry system can optimized process and cost saving because reduce 2 man power, 1 line production before use 3 man power and now only 1 man power for handle line production