Award ID: 689 Company: Purpose AM Systems

Allgemeine Informationen

- Datum: 2020-04-30 18:01:33

- Firma: Purpose AM Systems

- Ansprechpartner: Herr Kristers Moisejs

- E-Mail: kristers@purposeams.com

- Anschrift: 3/11 Pulka, Riga, Lettland

- Telefon/Fax: 37126114922 /

- Land: Latvija

Beschreibung:

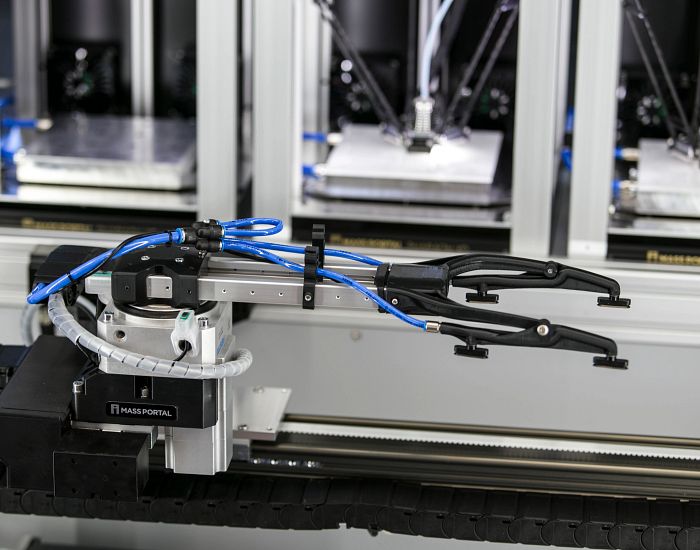

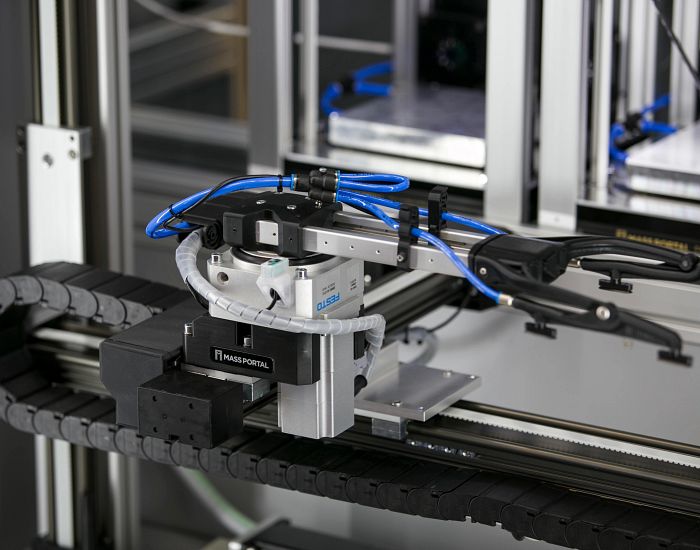

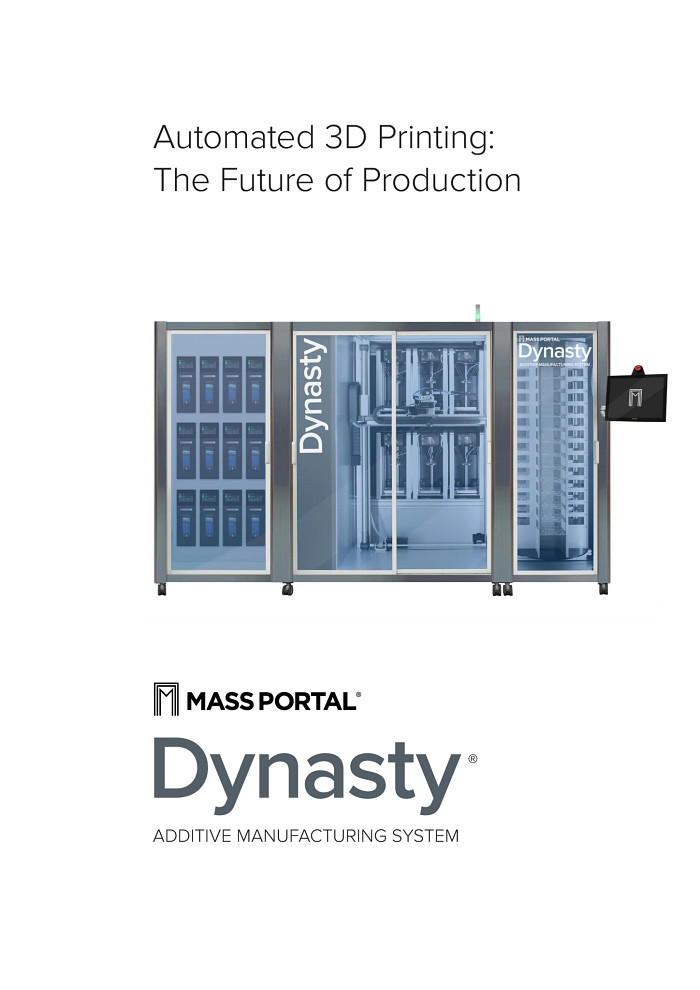

Purpose AM Systems has developed automation solutions for 3D printing. Automated gantry is connected to each 3D printer before the print job starts the gantry inserts new built plate after the print job is finished, the gantry takes build plate and moves it to storage. It can be scaled up to 50 3D printers. Combined with filament dryers, scanners, or different types of 3D printers (SLS, FFF, SLA) etc. 24/7 production solutions with 3D printers with trackable storage.

Problem:

3D printing is slow and time-consuming. With automation it is possible to scale this process, so make it faster and for shorter prints person doesn’t have to be in attendance to remove the part and start a new print. In a time like these with COVID when most 3D printing companies are printing some sort of protection for people automation would make their job easier and faster. Now, this is the perfect example of how 3D printing needs to be automated, but it’s just an example for other industries and production companies as well.

Lösungidee:

Time efficiency for 3d printing similar parts. Cost efficiency, because more parts can be produced in 24h without a workforce.