Award ID: 616 Company: JSL Solution Pte Ltd

Allgemeine Informationen

- Datum: 2020-03-11 06:03:22

- Firma: JSL Solution Pte Ltd

- Ansprechpartner: Mr. Jin Shuh Goh

- E-Mail: js_goh@jslsolution.com.sg

- Anschrift: 26 Kallang Place #03-12, Singapore

- Telefon/Fax: 96309603 /

- Land: Singapore

Beschreibung:

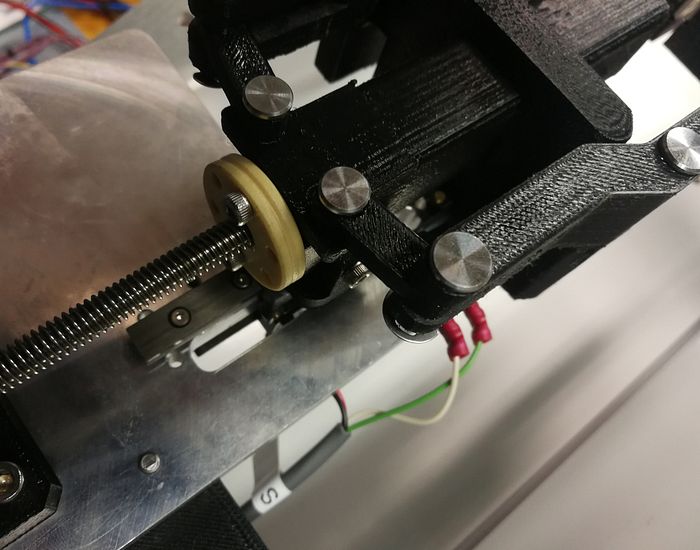

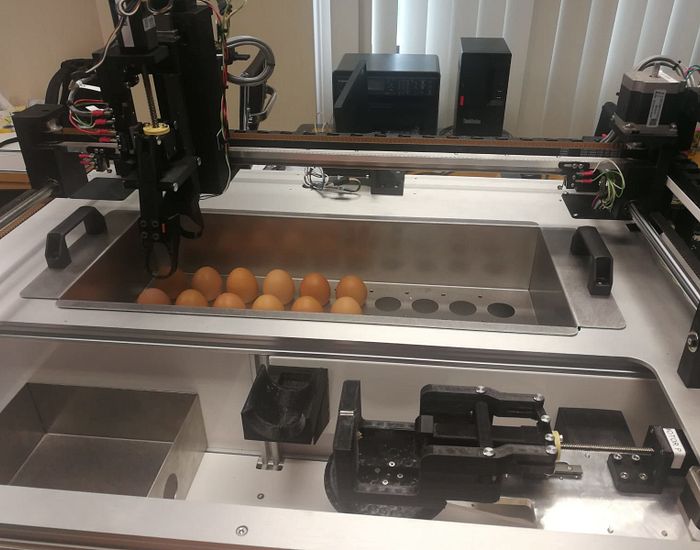

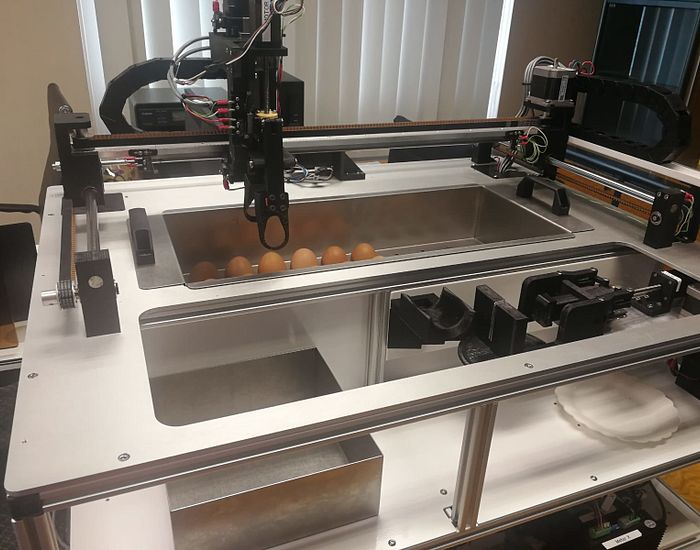

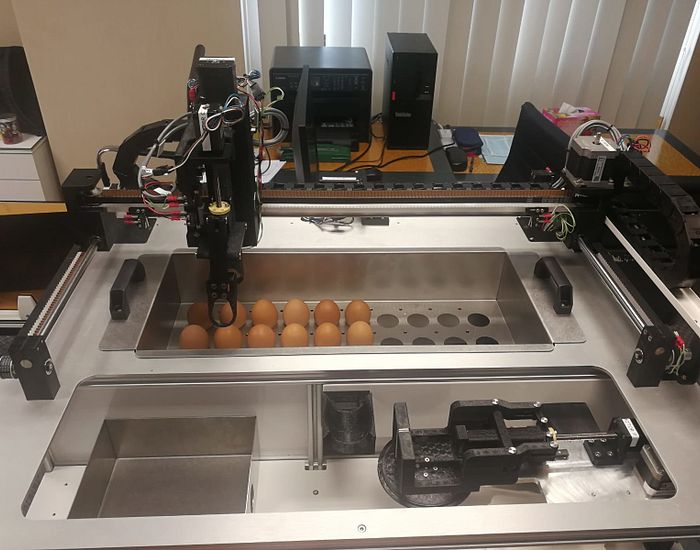

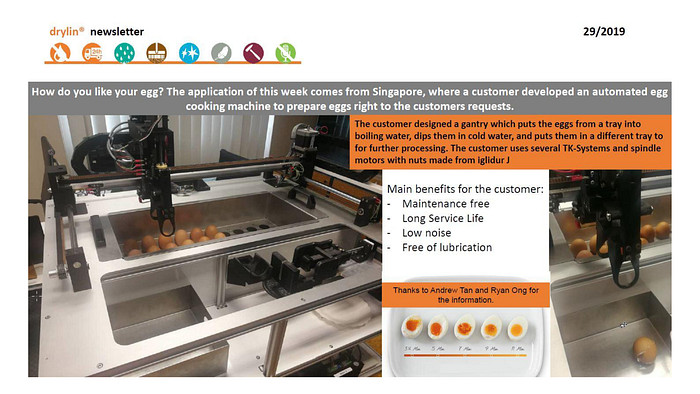

Therefore we came out an idea of half boiled egg cracking machine that able to cook and maintain the egg freshness, and with a push button, it able to crack and serve the egg freshly to the customer. The idea developed with Igus lead screw, motors, slider as well as it serve the food industry safe and hygiene purpose which is maintenance free and free of lubrication and overall prototype we using 3D printer to print major of the parts and using arduino controller to prove the concept.

Moreover the equipment idea was designed as modular so in future it able to integrate with Sunny Side & Scamble Egg Cooking equipment and further on with Toast making equipment.

Problem:

With our current proposal idea that serve half boiled egg (Singapore style breakfast), further integration with Sunny Side & Scramble Egg cooking equipment, it help to allocate the manpower to more value job and enchance customer experience thorugh better services.

Also the food safe handling and hygiene issue occur especially on recently due to Covid19 virus. It’s a huge problem where the food been handle by human when they not aware about personal health and transmit it to the population.

Beside that, food waste management also important for a business operation as top 3 major cost of F&B retails was labour, purchase of goods and material, and space. Therefore with industry 4.0 technology integrated in our equipment, we able to provide usage data for better control of inventory therefore enchance on food quality as well.

Lösungidee:

It also help to improve food safe & hygiene as it handle by machine, better inventory management with data collection of daily safe and improve on food quality. With smaller footprint design idea, it allow F&B retail to maximize their workspace usage as well. Therefore this equipment help improve in daily productivity, reduce in operation cost through wastage reduction & inventory management that help increase the company revenue.

Currently we are proposing this idea & prototype to Singapore gorvernment for further improvement in capacity, sizes, spped and launch the product in local and oversea market.